* Complete simulation of ProTool configuration (Windows CE-based systems) Ī complete configuration can be simulated quickly and efficiently on the configuration PC: The entire HMI target system is displayed on the configuration PC. * Functional enhancements for multifunctional platforms (MP 270B 10"/MP 370) * Function block library for predefined/user-defined picture elements * Flexibility thanks to Visual Basic Script and OLE-Automation * Logging with log editor for time-driven and event-driven project documentation * Process visualization via Windows-compliant user interface with predefined screen objects * Efficient configuration with short familiarization time The functions described below are determined by the device used. SIMATIC ProTool/Lite is a low-cost subset of SIMATIC ProTool and as such is limited to configuring the text-based devices (Text Panels), the small graphics devices (Panels of the 170 series) and the Mobile Panels 170 as well as the HMI part of SIMATIC C7 1). With SIMATIC ProTool, SIMATIC operator panels ranging from the Text Panel through to the Multi Panel can be configured. * Can be used worldwide thanks to extensive language support, also for Asian ideographic languages * Export/import of all texts of a project for easy translation. * Complete simulation of the project including variable simulation at the configuration PC – even without the PLC and the panel. * Library management for structured storage of reusable graphics objects * Graphics libraries with a large selection of graphics objects that are ready to use * Display editor with comprehensive possibilities for fast and efficient configuring of displays * Straight-forward configuration that is easy to change thanks to object-oriented symbolic data management and cross-reference lists with direct access at the click of the mouse button. through the standard operating mechanisms of Windows, validity checks, integral online Help with direct assistance and the copying of project data from one project to another * Shorter familiarization time and efficient configuration Į.g.

This means reduced maintenance and service costs and investment security. Projects can be ported to different HMI platforms.

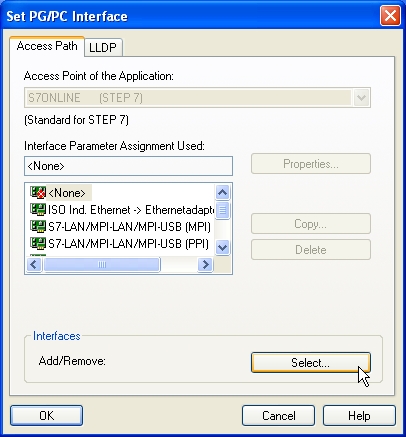

* Once configurations have been created, they can be easily reused within the system family. management of HMI projects using SIMATIC Manager within STEP 7 projects and sharing of STEP 7 data such as symbol tables, communications parameters and signaling systems * Integral component of Totally Integrated Automation (TIA):Įnhanced productivity, reduction of engineering outlay, reduction of lifecycle costs thanks to integration in STEP 7 i.e.

1) Under the tab "Integration" you can find a list of configurable operator panels.

0 kommentar(er)

0 kommentar(er)